The Philippines is a hard-working country rich in culture, history, religion, and nature, and rich in language skills. About 85% of the population speaks English, and with a high level of education, the country has many elements to lead the world as an industrialized nation.

ITO-SEISAKUSHO PHILIPPINES CORPORATION (based in the Philippines) manufactures advanced progressive dies and press parts based in the Carmelray Industrial Park II, inside the PhilippineEeconomic Zone in Laguna Province.

Blessed with excellent human resources with excellent English language skills, the company has established an integrated production system with local staff through aggressive capital investment and training.

In September 2017, a plant dedicated to progressive dies started operation, and we have been exporting our products to ASEAN countries and in North American region.

In addition to the Philippines, we have received patronage from many customers.

We will continue to actively pursue technological development and research and make further effort to contribute to the Philippine economy and related companies.

Company Profile

| Establishment | March 2003 |

|---|---|

| Company Name | ITO-SEISAKUSHO PHILIPPINES CORPORATION |

| Representative | Chairman: Sumio Ito Vice Chairman: Rosemarie Andrion President: Jaejin Kim |

| Capital stock | 30 million pesos |

| Employees | 120 employees |

| Location | Lot C2-1B Carmelray Industrial Park II, Brgy. Punta, Calamba City,Laguna Philippines 4027 TEL : +63-49-545-5152 FAX : +63-49-545-4123 E-mail : sales@ispc.com.ph |

| Main Business | Design and manufacture of progressive dies, processing of pressed parts, and assembly of parts |

| Main production items | Progressive dies and tandem dies for Automotive-related parts (onboard electronic components, wire harness parts, airbags, oil filters, mufflers, etc.) Parts for office automation (OA) equipment |

| Major Customers | DENSO Philippine Corporation DENSO TEN Philippines Corporation Imasen Philippine Manufacturing Coporation JAE Philippines, Inc. JOYSON SAFETY SYSTEMS (Philippines) Sumi North-Philippines Wiring Systems Corporation Vacuumtech Phils. Inc.(THERMOS) Yamashin Filter Manufacturing Corporation YUTAKA Manufacturing Philippines Inc. |

| Bank for transactions | MUFG Bank, Ltd.、Metropolitan Bank and Trust Company |

Technical information

Design

- We can exchange data with the head office and provide mutual support.

- We use the same CAD/CAM system as our headquarters.

- The level of local technicians who received training at the head office improves year by year, enabling local employees to design dies on their own.

Die making

- We have a well-equipped facility, including a machining center with a maximum work size of 2000×1000.

- All processes such as high-precision wire cutting, surface grinding, forming grinding and assembly can be done locally.

Stamping

- Equipped with 25 progressive press machines including a 300-ton press machine, we have been educated on the “labor-saving” system of the head office, and pursue high quality, low cost, and high productivity.

- We have 13 tandem press machines, 7 spot welding machines, and 5 tapping machines, allowing us to handle various processes.

Quality control

- Equipped with a CMM, our trained technicians from Japan use various measuring tools to check the product accuracy. We have a proven track record of meeting quality requirements even more stringent than those in Japan.

- We deploy more personnel than in Japan for product appearance checks and conduct thorough quality control.

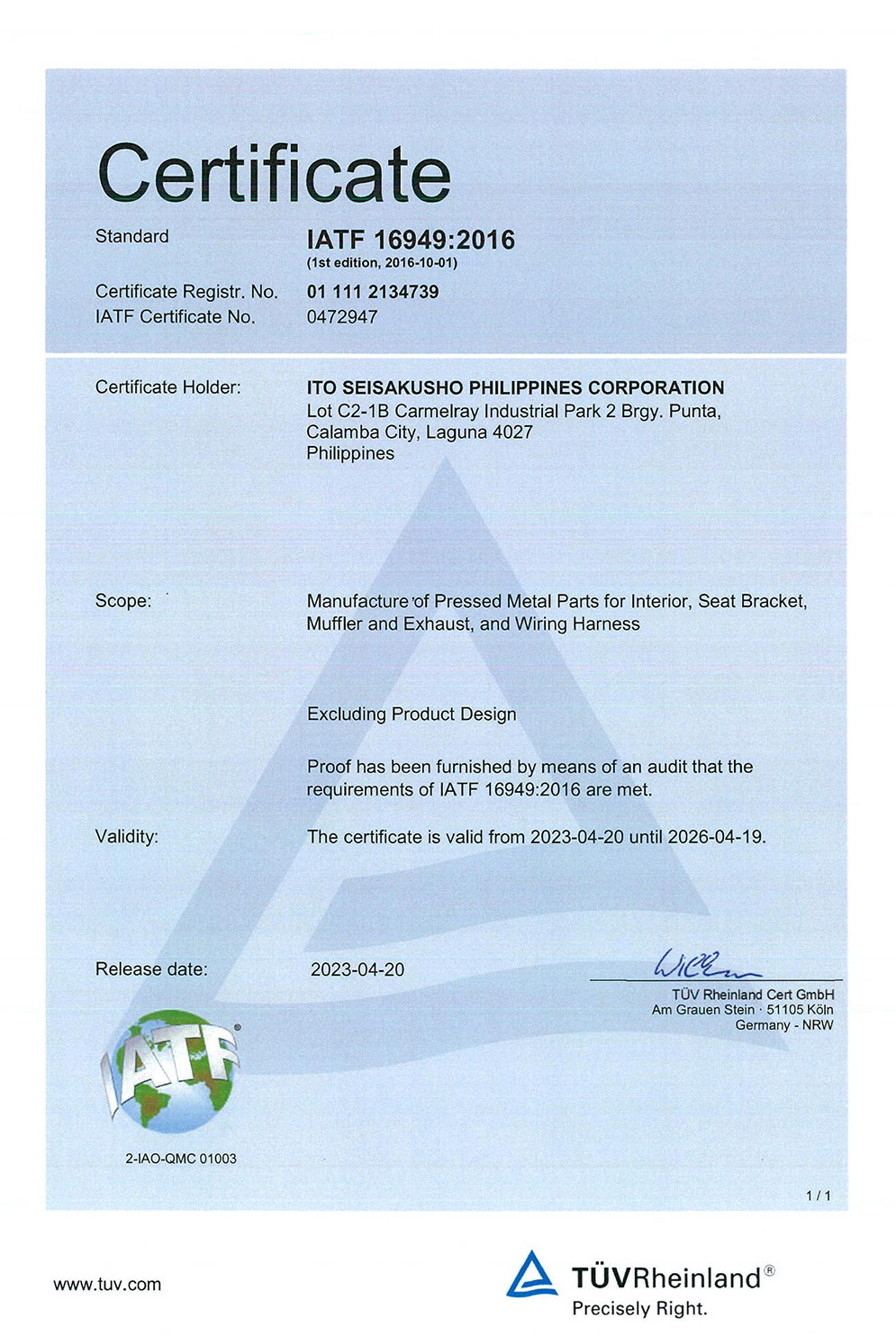

- In 2015, we obtained “ISO 9001” and “ISO 14001” certifications.

- In 2023, we obtained “IATF 16949” certification.

IATF 16949

ISO14001

List of Main Products

-

Antenna and security-related parts

-

Airbag parts

-

Speedometer (Thomson type)

-

Bracket for harness

-

Busbar

-

Muffler

Equipment information

List of tool & die Factory Equipment

Machining Center

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| Machining Center | VS10000 | Mori Seiki | X=2000 Y=1000 Z=600 ATC 90 | 1 |

| VS8000 | Mori Seiki | X=1600 Y=860 Z=600 ATC 60 | 1 | |

| VS50 | Hitachi Seiki | X=1000 Y=510 Z=450 ATC 20 | 1 | |

| M-3XD | Kitamura | X=760 Y=510 Z=510 | 1 | |

| N.C Milling Machine | M-2V | Mazak | X=1300 Y=300 | 1 |

E.D.M.

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| Wire Cut E.D.M. | AG400L | Sodick | X=400 Y=300 Z=250 | 1 |

| VL400Q | Sodick | X=400 Y=300 Z=220 | 1 | |

| AQ537L | Sodick | X=570 Y=370 Z=350 | 1 | |

| SL600G | Sodick | X=600 Y=400 Z=350 | 1 | |

| AP450L | Sodick | X=450 Y=300 Z=150 | 1 | |

| MV1200S | Mitsubishi | X=400 Y=300 Z=220 | 1 | |

| MV2400R | Mitsubishi | X=600 Y=400 Z=310 | 1 | |

| E.D.M. | NE30 | ARD | X=250 Y=200 Z=250 | 1 |

CAD/CAM

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| CAD/CAM | – | Eaton | – | 1 |

| New Partner V | Sum System | – | 4 | |

| CAD | Basic CAD | Excess Hybrid | – | 1 |

Others

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| Forming Grinder | L-350B | Okamoto | X=400 Y=150 | 1 |

| ACC-350Ⅱ | Okamoto | X=350 Y=150 | 1 | |

| PFG 350DX | Okamoto | X=350 Y=150 | 1 | |

| KGS-616S | Kent | X=410 Y=160 | 1 | |

| MIESTER V3 | Amada | X=350 Y=150 | 1 | |

| GS-45HR | Kuroda | X=450 Y=150 | 1 | |

| Surface Grinder | PSG-208DX | Okamoto | X=2000 Y=800 | 1 |

| PSG-156DX | Okamoto | X=1500 Y=600 | 1 | |

| PSG-95DX | Okamoto | X=900 Y=500 | 1 | |

| PSG-63DX | Okamoto | X=600 Y=300 | 1 | |

| Radial Drill Press | YD3-94CTN | Yoshida | – | 1 |

| YR5-130 | Yoshida | – | 1 | |

| TF-1700H | Tone Fan | – | 1 | |

| Lathe Machine | LE-19T | Wasino | – | 1 |

| Contour Machine | AMG-16 | Amada | – | 1 |

| Mechanical Shear | M2560 | Amada | t=5.5mm; max=6mmt | 1 |

| Blasting Machine | TSA-110 | Rich Sou | – | 1 |

| Press Machine | NC2-1600(1)E | Aida | 160tons Trial Machine | 1 |

List of Equipment in Press Factory

Press Machine

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| Press Machine: Progressive line | PMX-L2-3000(1) | Aida | 300tons w/N.C Feeder t=4.5 w=400 | 2 |

| NCS-250(1) | Aida | 250tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NS2-2500(1NL) | Aida | 250tons w/N.C Feeder t=3.2 w=300 | 1 | |

| E2W-200 | Komatsu | 200tons w/N.C Feeder t=3.2 w=300 | 2 | |

| NS2-1600(1NL) | Aida | 160tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NC2-16(2)A | Aida | 160tons w/N.C Feeder t=3.2 w=300 | 1 | |

| PXL-150 | Washino | 150tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NS1-1500(1NL) | Aida | 150tons w/N.C Feeder t=3.2 w=300 | 1 | |

| TPL150FX | Amada | 150tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NC2-110(2) | Aida | 110tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NC2-1100(1)E | Aida | 110tons w/N.C Feeder t=3.2 w=300 | 2 | |

| NC1-1100(1)E | Aida | 110tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NS1-1100(1NL) | Aida | 110tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NS1-1100 (1) | Aida | 110tons w/N.C Feeder t=3.2 w=300 | 1 | |

| TP110EX-X | Amada | 110tons w/N.C Feeder t=3.2 w=300 | 1 | |

| 100SII-L | ISIS | 110tons w/N.C Feeder t=3.2 w=300 | 1 | |

| 100S | ISIS | 110tons w/N.C Feeder t=3.2 w=300 | 1 | |

| 80S | ISIS | 80tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NC1-800 (1NL)E | Aida | 80tons w/N.C Feeder | 1 | |

| PXL 80AN | Washino | 80tons w/N.C Feeder | 1 | |

| TPL 60SI | Amada | 60tons Air Feeder | 1 | |

| NC1-600(1) | Aida | 60tons Air Feeder | 1 | |

| OBS 45-33B | Komatsu | 45tons w/Air Feeder | 1 | |

| PUX-35 | Amada | 35tons Air Feeder | 1 | |

| Press Machine: Tandem line | NC1-80(1) | Aida | 80tons | 1 |

| PUX 80AD-KRK | Washino | 80tons | 1 | |

| TP80EX-X | Amada | 80tons | 1 | |

| TP-60 | Amada | 60tons | 2 | |

| OBS45-33B | Komatsu | 45tons | 1 | |

| PUX-35 | Washino | 35tons | 1 | |

| PUX-15 | Washino | 15tons | 3 | |

| OBS-15-B | Komatsu | 15tons | 1 |

Others

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| Spot Welding | SLP-35B5 | Nastoa | 35KVA | 7 |

| Tig Welder | 300P | Daiden | 300A | 1 |

| Tapping Machine | BT1-215 | Brother | M3,M4 | 1 |

| BT1-216 | Brother | M3,M4 | 1 | |

| BT2-225 | Brother | M3,M4,M5,M6 | 1 | |

| 01BB-TMS | Toyosk | M5 | 1 | |

| 01CC-TMS | Toyosk | M3,M5 | 1 | |

| Compressor | ZV37AS3i-R | Mitsui Seiki | Max.Working Pressure-7.0bars/9.0 | 1 |

| ZV22AX-R | Mitsui Seiki | Max.Working Pressure-7.0bars/9.0 | 1 | |

| ZV15AS5-R | Mitsui Seiki | Max.Working Pressure-7.0bars/9.0 | 1 | |

| Arc Welder | 300 | Yamato | 300A | 2 |

| Degreasing Machine | UWPB-24164 | Unicleaner | – | 1 |

| DIPPING TYPE | ISTECH | – | 1 | |

| Generator Set | C250D6 | AGG-CUMMINS | 250KVA, 3P, 230V | 1 |

Measurement equipment

Measuring Machine

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| 3D Coordinate Measuring Machine | CRYSTA APEX 544 | Mitutoyo | X=500 Y=400 Z=400 | 1 |

| Visual Measuring Machine | QS-L2010Z/AFB | Mitutoyo | X=200 Y=100 Z=150 | 1 |

| Profile Projector | PJ-H3000P | Mitutoyo | – | 1 |

| Image Dimension Measuring | IM-8030 | Keyence | X=300 Y=200 | 1 |