Indonesia boasts the largest population in Southeast Asia and continues to grow economically. It is a pro-Japanese country, with annual automobile production and sales exceeding 1 million units and approximately 96% of vehicles sold are Japanese, making it an attractive market.

PT. Ito Seisakusho ARMADA (based in Indonesia) is the 47th company of the New Armada Group, an Indonesian conglomerate, and was started as a joint venture with PT.

The factory is located in Bekasi Regency, approximately 50 km east of Jakarta.

Engineers from the Philippine base were also stationed at the start-up, and within just two months of the establishment of the plant, advanced progressive dies were manufactured.

As a new base of the Ito-Armada Group, we will redouble our effort to contribute to the Indonesian economy.

Company Profile

| Establishment | October 2013 |

|---|---|

| Company Name | PT. ITO SEISAKUSHO ARMADA |

| Telephone | +62 21 882 3252 |

| Representative | Chairman: J. Budiyono President: Tsuyoshi Kawasaki Vice President: Charles H.W. |

| Capital stock | 70 billion rupiah Ito Seisakusho Co., Ltd 51% PT.MEKAR ARMADA JAYA 49% |

| Employees | 70 employees |

| Head Office Location | Greenland International Industrial Center GIIC-Kota Deltamas, Blok AI No.1 Desa Nagasari, Kec. Serang Baru Kabupaten Bekasi, Jawa Barat. TEL (021)39702120 Person in charge Kawasaki |

| Main production items | Design and manufacture of progressive dies, processing of pressed parts, and assembly of parts |

| Bank for transactions | MUFG Bank, Ltd.、Mandiri Bank |

| Major Customers | PT.AUTOCOMP SYSTEMS INDONESIA PT.FUJI SEAT INDONESIA PT.FUTABA INDUSTRIAL INDONESIA PT.TD AUTOMOTIVE COMPRESSOR INDONESIA PT.TOYOTA BOSHOKU INDONEISA PT.TOYOTA BOSHOKU DEVICE INDONEISA PT.T.RAD INDONESIA PT.MEKAR ARMADA JAYA |

Technical information

Design

- We use the same CAD/CAM system as our headquarters.

- It is possible to exchange data and provide mutual support among each location.

Die making

- We have a well-equipped facility, including a machining center with a maximum work size of 2000×1000.

- All processes such as high-precision wire cutting, surface grinding, forming grinding, and assembly can be done locally.

Stamping

- Equipped with 15 progressive press machines including a 300-ton press machine, we have been educated on the “labor-saving” system of the head office, and pursue high quality, low cost, and high productivity.

Quality control

- Equipped with a CMM, our trained technicians from Japan use various measuring tools to check the product accuracy. We have a proven track record of meeting quality requirements even more stringent than those in Japan.

- In 2016, we obtained “ISO/TS 16949” certification.

- In 2018, we obtained “IATF 16949” certification.

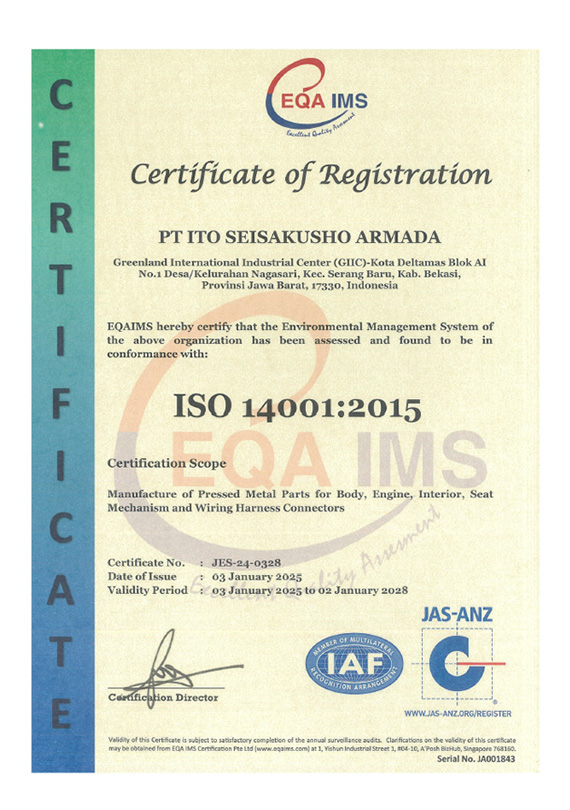

- In 2025, we obtained “ISO 14001” certification.

IATF 16949

ISO 14001

List of Main Products

-

Seat-related parts

-

Bracket

-

Body-related parts

-

Radiator

-

Exhaust system

Equipment information

List of tool & die Factory Equipment

Machining Center

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| Machining Center | V99L | Makino | X=2000 Y=1000 Z=600 ATC 60 | 1 |

| V56I | Makino | X=900 Y=550 Z=450 ATC 60 | 1 |

E.D.M.

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| Wire Cut E.D.M. | SL600G | Sodick | X=600 Y=400 Z=350 | 1 |

| SL400G | Sodick | X=400 Y=300 Z=250 | 1 | |

| MV 2400S | Mitsubishi | X=600 Y=400 Z=300 | 1 | |

| MV 1200S | Mitsubishi | X=400 Y=300 Z=250 | 1 | |

| E.D.M. | T50 ZNC | SANE KUEI Machinery | X=300 Y=200 Z=200 | 1 |

CAD/CAM

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| CAD/CAM | SOLIDWORK-2018 Professional | SOLIDWORK-2018 | – | 1 |

| SOLIDWORK-3D Basic CAM | – | – | 1 | |

| CAD | Full Version-Lic. No. UTH5531 | Excess Hybrid by CGS | – | 1 |

| 3D Modeling-Lic. No. UTH5129 | – | – | 1 | |

| 3D Modeling-Lic. No. UTH5347 | – | – | 1 | |

| CAM | CAM-Lic. No. UTH5229 | Excess Hybrid by CGS | – | 1 |

| 3D CAM-Lic. No. UTH5344 | CamTool by CGS | – | 1 | |

| 2D WEDM CAM | CAM MAGIC by Mitsubishi | – | 1 | |

| CAE | CG PRESS-Lic. No. UTH5231 | SOLIDWORK-2018 (Add On) | – | 1 |

Others

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| Forming Grinder | Linear 350Ⅱ | Okamoto | X=350 Y=150 | 2 |

| Surface Grinder | ACC-208DX | Okamoto | X=2000 Y=800 | 1 |

| ACC-105D | Okamoto | X=1000 Y=500 | 1 | |

| Proth | Proth | X=800 Y=500 | 1 | |

| Milling Machine | SM4 | Standard | X=780 Y=406 Z=406 | 1 |

| Radial Drill Press | TPR 1600 H | Tailift | – | 1 |

| Lathe Machine | LA -530 x 1100 | LEI SHIN | – | 1 |

| Sandmaster | – | Sandmaster | – | 1 |

| Tig Welding | ACCUTIG 300P | OTC | – | 1 |

List of Equipment in Press Factory

Press Machine

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| Press Machine: Progressive line | PMX-3000 | Aida | 300tons w/N.C Feeder t=6.0 w=600 | 1 |

| L2M-300 | Komatsu | 300tons w/N.C Feeder t=4.5 w=400 | 1 | |

| NS2-2000 | Aida | 200tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NS1-2000 | Aida | 200tons w/N.C Feeder t=4.5 w=500 | 1 | |

| SDEW-2025 | Amada | 200tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NC2-1600 | Aida | 160tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NS2-1100 | Aida | 110tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NC2-1100 | Aida | 110tons w/N.C Feeder t=3.2 w=300 | 1 | |

| TP-110EX | Amada | 110tons w/N.C Feeder t=2.3 w=200 | 1 | |

| TPL-110 | Amada | 110tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NS1-800 | Aida | 80tons w/N.C Feeder t=3.2 w=300 | 1 | |

| NC1-800 | Aida | 80tons w/N.C Feeder t=3.2 w=300 | 3 | |

| OBS-45 | Komatsu | 45tons w/Air Feeder | 1 |

Others

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| Spot Welding | SLP 35A5 | Nastoa | 35KVA | 6 |

| SLP 50A5 | Nastoa | 50KVA | 2 | |

| Compressor 22KW | OSP-22S5ANA | Hitachi | Max.Working Pressure-7.0bars/9.0 | 2 |

| Compressor 15KW | OSP-15S5ANA | Hitachi | Max.Working Pressure-7.0bars/9.0 | 1 |

| Overhead Crane 3T | 3MC6_3TC5_TLU5-28 | Hitachi | 3Ton | 3 |

| Overhead Crane 2T | 2MC6_3TC5_TLU5-28 | Hitachi | 2Ton | 1 |

| Gantry Crane 3T | – | Hitachi | 3Ton | 2 |

| Gantry Crane 2T | – | Hitachi | 2Ton | 2 |

Measurement equipment

Measuring Machine

| EQUIPMENT | TYPE | BRAND | CAPACITY | SET |

|---|---|---|---|---|

| 3D Coordinate Measuring Machine | Crysta-Apex S544 | Mitutoyo | X=500 Y=400 Z=400 | 1 |

| Profile Projector | PJ-A3010F-200 | Mitutoyo | – | 1 |

| Countracer | CV-3200S4 | Mitutoyo | – | 1 |

| Welding Checker | SP-3288 | Spotron | – | 1 |

| Coating Thickness Gauge | Permascope MP0-FP (605-362) | Fischer | – | 1 |